The quality level of insulit

The Belgian specialist in impact sound insulation

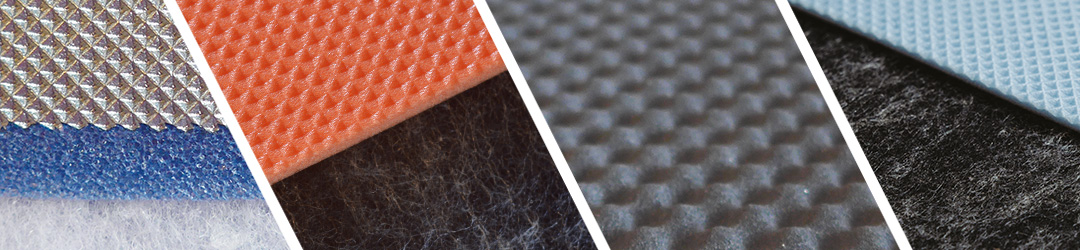

Since 1980, insulco has been dedicated to the development, production, and supply of thin materials reducing the transmission of impact and shock noise between floors. Some of these underlays are also used for thermal insulation under the screed.

Quality materials, fast installation, high performance, and efficiency maintained over time are among the advantages of insulit (formerly Alveolit) underlays. Our acoustic underlays have become a reference in the fight against impact noise. For almost 40 years, insulit foams have been installed in Belgium and throughout the world on the most important projects, representing millions of m².

The range includes many benefits :

1) Unique quality

insulit is produced from a foam with unique properties, polyolefine (polyethylene with a closed-cell structure, cross-linked by a physical process without chemical additives). Unlike foams that have been produced by a chemical extrusion process, which present a high risk of creep, the exclusive physical cross-linking process of insulit guarantees high performance and outstanding resistance to crushing over time.

2) The best performance on the market

The insulit range helps you to respond to all possible configurations and achieve the best results, depending on requirements and budget. The insulit underlays provide a solution that will give values between 23 and 35 dB (∆Lw).

3) Also reduces airborne noise

One of the basics in impact sound insulation is to obtain the product with the lowest dynamic stiffness. It is verified by its resonance frequency and gives a result in MN/m³. The lower this value, the better the result obtained.

Moreover, the incidence of this low dynamic stiffness allows to obtain a better comfort to airborne noise by the phenomenon of mass-spring-mass. The insulit range has the lowest values on the market, which contributes to an improvement of 3 to 8 dB in the Rw value of the total floor, depending on the product. (see standard EN 12354-1). insulco is equipped with this type of control equipment.

4) Results proved by recent test reports

Recent test reports carried out in an external laboratory (BBRI) guarantee the performance of the underlays. All the results are available on request. The good result obtained allow the underlays to meet or even overtake the latest standards in force.

5) Low creep

The insulit underlays have to maintain their initial performance throughout the whole lifespan of the building where they are installed. Every material is meticulously tested in our own laboratory, where we monitor the material deformation over time when placed under a constant pressure.

The insulit underlays withstand high loads without deforming. They are suitable for the most common applications: residential buildings, schools, hotels, offices buildings, hospitals, etc.

6) Low resonance frequency

A good acoustic underlay must display a low dynamic stiffness or a low resonance frequency, which will guarantee better impact sound insulation results and remarkably higher insulation against airborne noises.

7) Low emissions (VOC)

With an extremely low VOC (Volatile Organic Compounds) content, insulit underlays are largely below the maximum levels explicited by European standards and labels. The components of our underlays do not deteriorate over time and do not present any risk to public health.

8) Continuous quality assessment

Every production batch is meticulously monitored by our internal laboratory by checking the characteristics of the products. This approach guarantees a constant high level of quality.

9) Internal laboratory

insulco has built its own acoustic and thermal testing laboratory inside the production site. It plays an important role in the development of new solutions and continues to bring buildings to ever-higher levels of acoustic comfort. The laboratory takes part in the permanent and strict control process of the production, making the range one of the most reliable on the market.

Find out more about our laboratory.

10) Quality products require quality advice

As a specialist in underlays for screeds, our acoustics department has a technical department available to provide the acoustician, architect or contractor with personalised advice. We can be at your side from the choice of the solution best suited to your project to its implementation, which will have to meet the specific requirements of the building site.