insulWood

The solution for wooden structure

The acoustic underlay for wooden structures

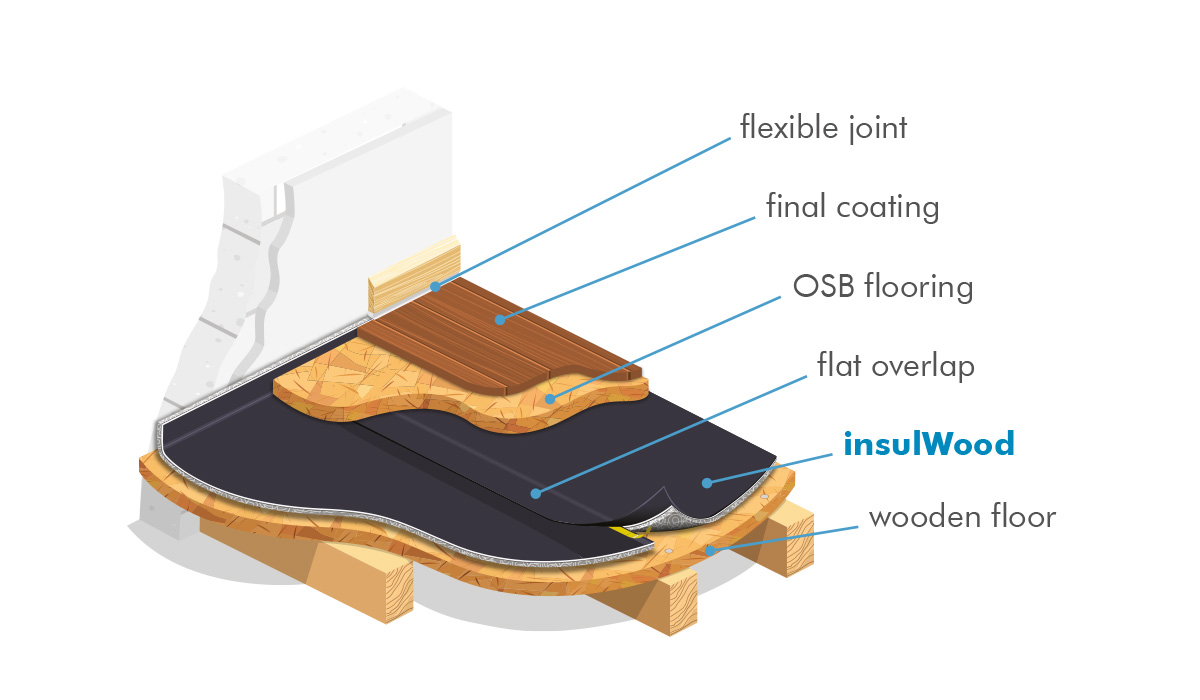

insulWood is the ideal insulation to soundproof lightweight and timber floors against impact and airborne noises in a building. Light structures demand specific materials; thus the chosen layers of the underlay were selected to perform and to behave in accordance to the mass-spring-mass effect even with a lightweight floating floor. insulWood both suits to new construction and renovation. It brings an extremely satisfying acoustic performance that other so thin materials could not supply.

insulWood is a thin and efficient solution that avoids increasing too much the floor thickness. It can be applied to existing wooden flooring or new OSB.

HD foam + felt: a revolutionary acoustic underlay

insulWood is made of a high-density polyethylene film laminated onto an acoustic foam made of a physically reticulated polyolefin foam with closed micro-cells, which has been assembled on a resilient acoustic felt. The overlapping junction provides airtightness, which contributes to reducing airborne noise.

Benefits

- High performance against impact noise.

- Better airborne noise insulation through the mass-spring-mass principle.

- High density film with a lateral, waterproof and adhesive joint to reduce airborne noise.

- Thin, integrated overlap (± 5 cm), no square metre loss.

- Thin, ≥ 7 mm only.

- Sold in rolls for a quick and easy installation.

- Easy to lay alongside the walls, thus preventing lateral acoustic transmissions.

- Very smooth and resistant structure. During the installation, it is easy to glide the panels on the underlay.

|

Characteristics:Materials: HDPE film, acoustic polyolefin, Thickness: ≥ 7 mm (under 500 Pa) Colour: Black (HDPE film) / Grey (foam) / Black (felt) Dynamic stiffness: s’t = 5 MN/m³ (EN 29052-1) Mechanical resistance: 425 / 630 kPa Compression: ±15 % under 2 kPa (10% tolerance) Elongation: 140 % Roll size: 20 m x 1 m Weight: ±650 g/m² Overlaps: Flat adhesive overlap (±5 cm) |