insulWood

The solution for wooden structure

insulWood can be applied in many situations

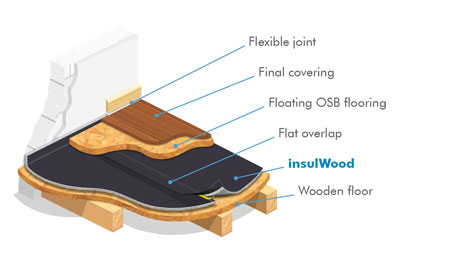

[A] With light wood framed constructions

insulWood can be installed on an existent wooden flooring or also on a new OSB flooring

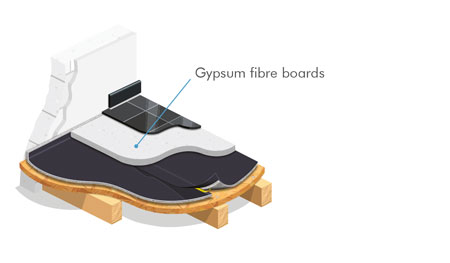

[B] With a light dry screed

insulWood can be placed under a dry screed (floating rigid panels) to allow e.g. the installation of a tiling.

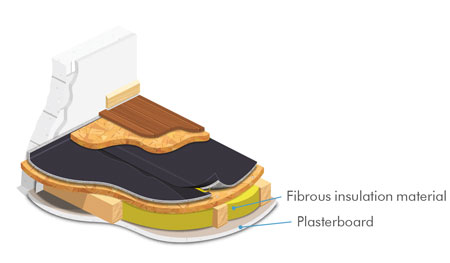

[C] With a dropped ceiling under flooring

A layer of fibrous insulation material between the joists provides a better thermal and acoustic comfort.

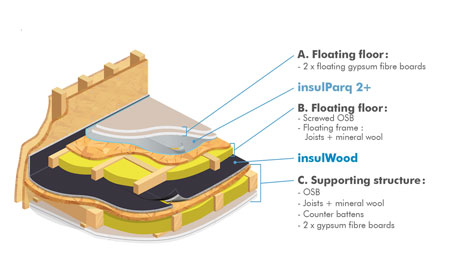

[D] With a dropped ceiling and floating frame

The installation of the insulWood acoustic underlay has to be performed under a floating frame. By doing so, the flooring is uncoupled from the remaining building fabric, and thus, the noise transmission between the floors is strongly limited.

Installation

1) Unroll the insulWood underlay by starting against a wall, and make sure that the non-adhesive side is facing the wall. The black felt has to be placed towards the ground and the HDPE film must face the ceiling.

2) Raise the insulWood acoustic underlay laterally against the wall.

3) Cut the underlay with a sharp cutter and unroll the next strip edge to edge (felt and foam) to the previous one. Afterwards, adjust the overlap on the double-sided tape of the adjacent strip.

4) Remove the protective layer in order to attach the lateral joint.

5) Repeat the previous steps until the surface is completely covered. Do not pierce the insulWood acoustic underlay under any circumstances. Otherwise, there will be a risk of acoustic bridges.

6)

– Configuration [A] and [C] Make a floating installation of laterally interlocking OSB panels (min. thickness: 18 mm) or lay down two 12 mm thick panels (crossed installation) which have to be mechanically attached to each other, without being attached to the underlay.

– Configuration [B] Place gypsum fibre boards with shiplap joints.

– Configuration [D] Make a floating wooden structure by using joists which are tied together and where the cavities are filled with fibrous insulation material. Afterwards, attach OSB panels (min. thickness: 18 mm) on the joists.

7) Install the final coating.

8) Cut off the excess lateral insulWood, place the plinth slightly higher than the floor and make a flexible, waterproof joint.